{student's last name} Engineering, Inc., has been asked to design and build a solution to an industrial transportation problem. {teacher's last name} Steel Incorporated, a major steel manufacturing company, requires a structure capable of continuously transporting railroad cars (containing new steel) across a river that separates the company's manufacturing building from the building used to store and ship the steel.

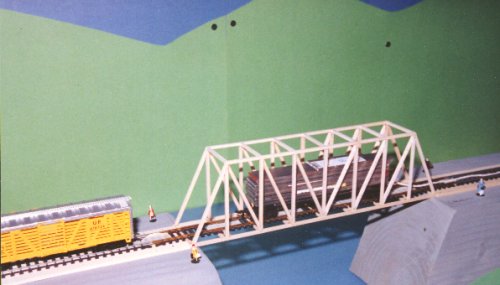

The clear span between supports is 12.0". No interior supports are allowed.

The weight of the railroad car (HO scale train - 1:87.1) plus it's load is approximately 38.9 oz. ( 1.10 kg).

A clearance of .25" to each side of the car and .9375" above the car is required. (The distance from the bottom of the rail assembly to the top of the car @ 2.25" and the width of the car is @ 1.375")

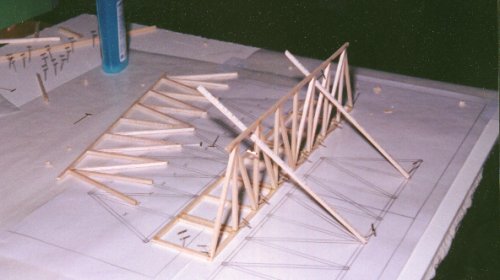

The building materials are limited to 1/8" x 1/8" balsa wood and water soluble glue.

The required safety factor for the structure is 1.5. Therefore, the structure should be tested with 1.5 times the actual working load. (Before testing the structure remove the top of the car and add steel plate to increase the weight of the car and load to 58.4 oz. - You may need to leave to top of the car off to test the structure.)

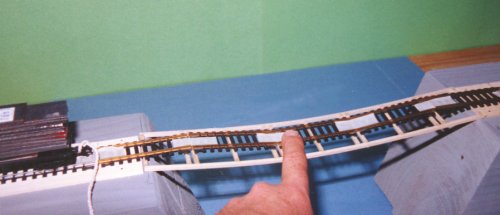

The track for the center span should be constructed of short 3" segments of track held together by masking tape. This is to prevent the track from providing a disproportionate amount of the load carrying capability. (You could also experiment with building your rails from balsa wood.)

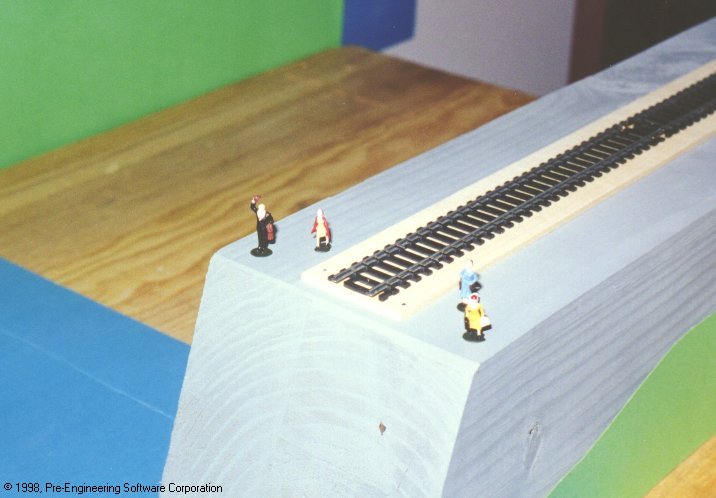

We built our support blocks from 6"x 6" x 24" southern pine. The track was not attached directly to the blocks. In order to elevate the track above the level of the support block, we placed a 1/8" x 2" piece of bass wood between the track and the support block. Both the bass wood and the track were attached to the block with 1/2" nails.